Many people want to use waste paper to start a production business, and many of them choose to produce egg trays because it is relatively simple, low investment, quick capital recovery, and the market is hot.

Here there are 5 points you should learn before starting.

Classification of egg trays

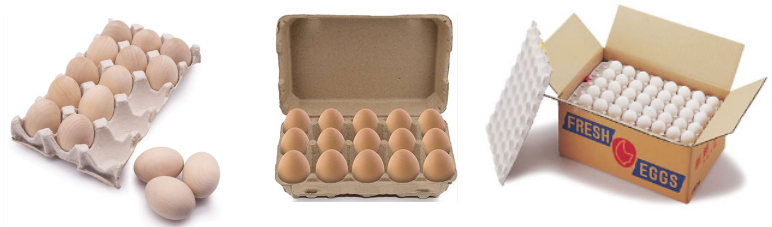

Egg tray, as the name suggests, is a container used to hold eggs, while egg tray machine production line and egg tray machine are machines used to make egg trays. Egg tray machine production line can make different types of egg trays according to different materials. Therefore, egg trays can not only be used to hold eggs. According to the different raw materials for making egg trays, egg trays are divided into the following types:

- Plastic egg trays: Plastic egg trays are made of plastic, but they produce colorful and beautifully shaped egg trays. Because of its high cost, it is generally used more in high-end supermarkets.

- Single egg tray: A single egg tray is generally used at home or in Western restaurants. It has the characteristics of a cute shape and convenient use, which can effectively prevent eggs from rolling off the table. It is an alternative small tableware for a stylish home.

- Tray-packed egg trays: tray-packed egg trays can hold dozens of eggs in one tray depending on the size, and are also the most commonly used egg packaging tools.

Industry background

Egg trays have been developed internationally for a long time, especially in Europe and the United States, where a relatively mature national product and market system has been formed.

According to its field of use, egg trays can be divided into transport packaging and consumer packaging. The former refers to the egg tray, and the latter refers to the egg box, which is used for the circulation process of eggs respectively.

Egg trays have been used throughout the transportation process, especially in long-distance transportation. (Currently, the 15kg plastic shipping boxes used in parts of China are largely non-existent).

Egg trays usually have 30 pcs of holes, except individual countries, such as Japan have 40 pcs of holes and Spain has 15 pcs of holes. Its material is mainly waste paper, called disposable pulp model tray, which accounts for more than 90% of the market share, and the rest of the plastic tray, which is most used in Taiwan, can be recycled after cleaning and disinfection. The reason for using a large number of paper mold trays is mainly to adopt its disposable characteristics, the purpose is to prevent the spread of viruses such as Newcastle disease in chickens, and at the same time avoid tedious disinfection and cleaning work, the specific effect.

The egg tray is still divided into different sizes according to the size of the eggs.

Plastic egg trays are mainly used for direct-to-consumer supermarkets and grocery stores, with 6, 10, 12, and 18 pieces, with various specifications, lift the lid and you can see the egg production date, manufacturer, advertising, publicity, and wholesale.

There are mainly two kinds of egg carton materials: pulp molding and foam, with a market share of 60% and 30% respectively, and plastic transparent board and cardboard, but from people’s current emphasis on environmental protection, more and more Molded pulp products replace Styrofoam eggs in boxes which are known as “white pollution”.

Egg wholesalers, buy eggs from chicken farms, wash, sort, pack, and then send them to retail stores such as supermarkets. They usually have their egg tray factories, or they have established close relationships with egg tray manufacturers.

However, a fairly large number of chicken farms have a large production volume, so they will use their egg trays, usually small and medium-sized equipment, to meet the needs of the surrounding areas.

How the egg tray production line is environmentally friendly?

For egg tray production lines, or many machinery, its environmental protection is now a concern, now many industries are paying attention to environmental protection, machinery in environmental protection is particularly important.

So, how is the environmental protection of the egg tray machine production line reflected in daily life?

Egg tray machine is the earliest pulp molding equipment, which mainly produces various pulp molding products, such as egg trays, bottle trays, fruit trays, seedling trays, etc.

Pulp molding products use waste newspapers and carton papers as the main raw materials, pulping through a certain proportion of additives, dehydration molding through special molds, and then drying, heat treatment, shaping and other series of technological processes.

Pulp molding products can be recycled and degradable. After adding special technology, they have good waterproof and oil-proof properties, and can completely replace foamed plastic products, which can effectively eliminate “white pollution” and have good environmental protection;

Pulp molded products are environmentally friendly products recommended by the world’s environmental protection departments because they attach great importance to environmental protection during their production process and avoid environmental impact.

The raw material is waste paper, and in the process of production and processing, it is mainly a physical reaction. Only a few chemicals are added as water repellants. After the products are dried, basically all of these chemical materials remain in the finished product without being discharged. Therefore, avoid causing pollution to the environment;

The water used in the egg tray machine production line is used in a closed cycle, when the product is dried, the water vapor is volatilized into the space, and there is no need to replenish it in the production process, so the water consumption is not large.

Why do people prefer paper pulp trays?

- The raw material of paper mold packaging products is waste paper, which will not cause obstacles to the environment and recycling and is conducive to the export of products by manufacturers.

- Paper mold packaging products have a wide range of applications.

With the advancement of paper mold technology, products that use foam as inner lining packaging can be replaced by paper molds.

- The investment is low.

The process of the paper mold is simpler than that of the foamed plastic, the production time and cycle are short, and the energy consumption and raw material cost are low.

- Paper mold products can be stacked and stored to reduce transportation and storage costs.

How to produce egg tray?

The first step is pulping. Put waste paper scraps into the pulping machine, add water and other raw materials, and crush them into pulp. This process is equivalent to recycling those scraps. It is the first step in their regeneration into egg trays.

The second step is forming. The beaten pulp is piped to the forming machine. Egg tray forming machine is referred to as egg tray machine. Different types of egg trays can be produced through different molds, and industrial packaging such as apple trays, wine trays, and seedling trays can also be produced by replacing the molds. Once shaped, the egg trays have their basic shape, but they are still wet. The next step is required.

The third step is drying. The drying path is very long, and the omnidirectional three-dimensional hot air ensures that the egg tray can be dried in a short time. The freshly formed wet egg trays are sent into the long drying tunnel and slowly move on the conveyor belt, feeling the hot air from all directions. It is this hot air that helps them remove the moisture from their bodies, and the waste paper is officially regenerated Egg tray.

The fourth step is packing. This link is to organize, pack, and squeeze the new egg trays for easy transportation and handling. Dozens of egg trays are sent to major chicken farms, shopping malls, and supermarkets to realize their rebirth value.

If you’re just getting started in the paper egg tray business, make sure you get my guide on the investment analysis to get your factory up and running.